The Wisdom of the Chinese - Multi-healds Pattern Loom in Han Dynasty(Part II)

The embodiment of the scientific and technological wisdom of the Chinese

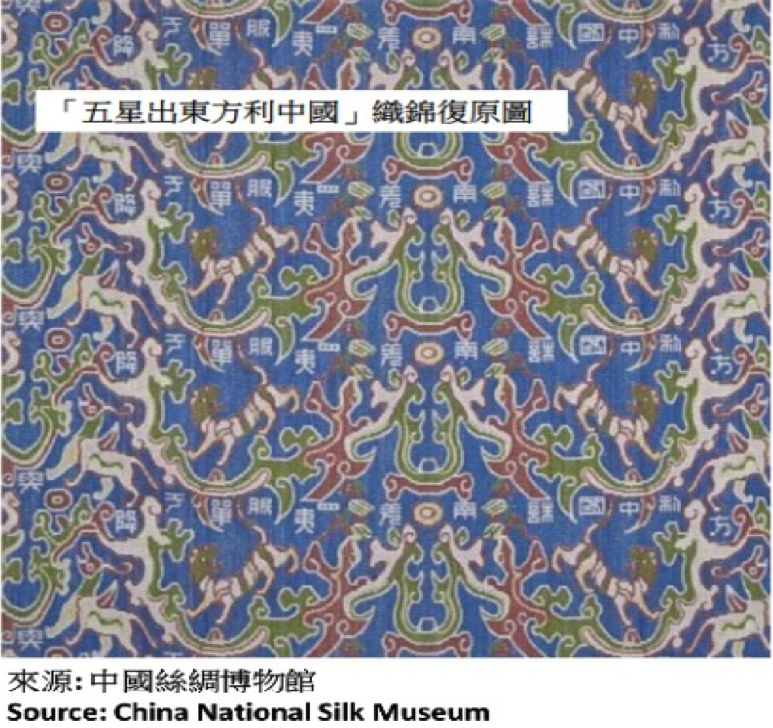

Weavers only need four steps to operate the pattern loom. Firstly, operate the tenoned tooth beam and select the heald. Each operation, only need to move the tooth beam one-step further to change a heald, because the required healds have been arranged in sequence according to the pattern requirements. Secondly, step on the treadle to raise the corresponding heald, and the heddle drives the warps to rise or fall, to form shedding. At this time, the weaver only needs to use a shuttle to "feed" a weft ". The last is "beating the weft", which means tightening the weft yarns. To repeat these four actions more than 200 times, the brocade pattern of "Five stars out of the east and benefit China" will come out. 1

1 From the following four steps, it is easier to understand the operation of the pattern loom how it works:

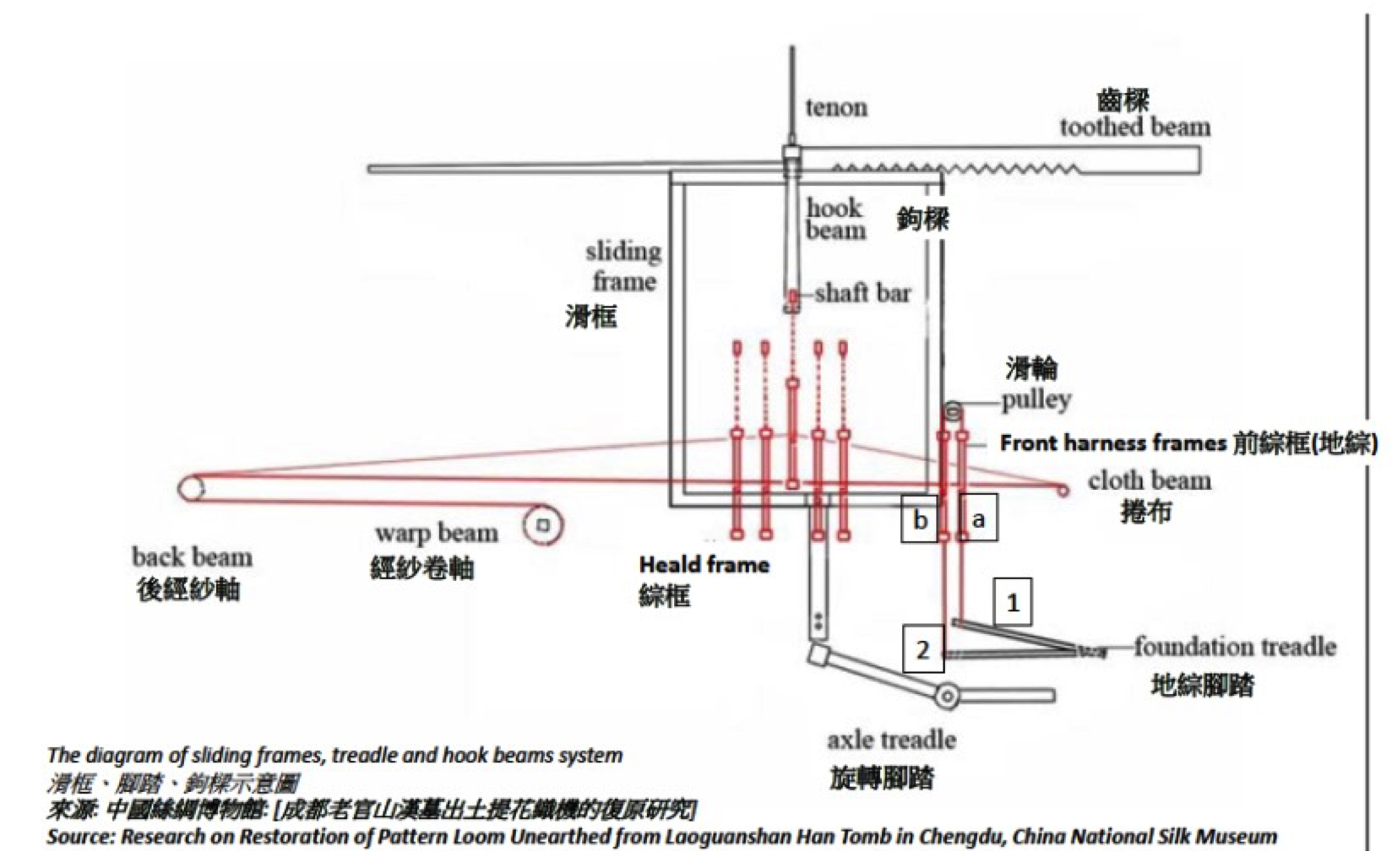

The first step is foundation shed. Firstly, step down the foundation treadle (a), the front harness frame (1) descends, lift up the front harness frame (2) through the pulley, this makes a shed for the weft yarn passed through.

The second step is the tooth beam is moved to select a tooth position so that the double hooks are aligned with the next pattern heald. Step down the axle treadle again. It jacks up the sliding frame and the double hooks continue to lift up the desired heald fame, which completes a shedding, and the weft yarn shuttle passes through.

Thirdly, step down the foundation treadle (b), the front harness frame (2) descends, lift up the front harness frame (1) through the pulley, tabby shed is formed for the weft passes through.

The fourth step is to repeat the pattern selection of the heald frames. Move the toothed beam so that the hook bar over the selected heald frame. Step down the axle treadle and lift the required pattern shaft to form the shed for the shuttle passing through

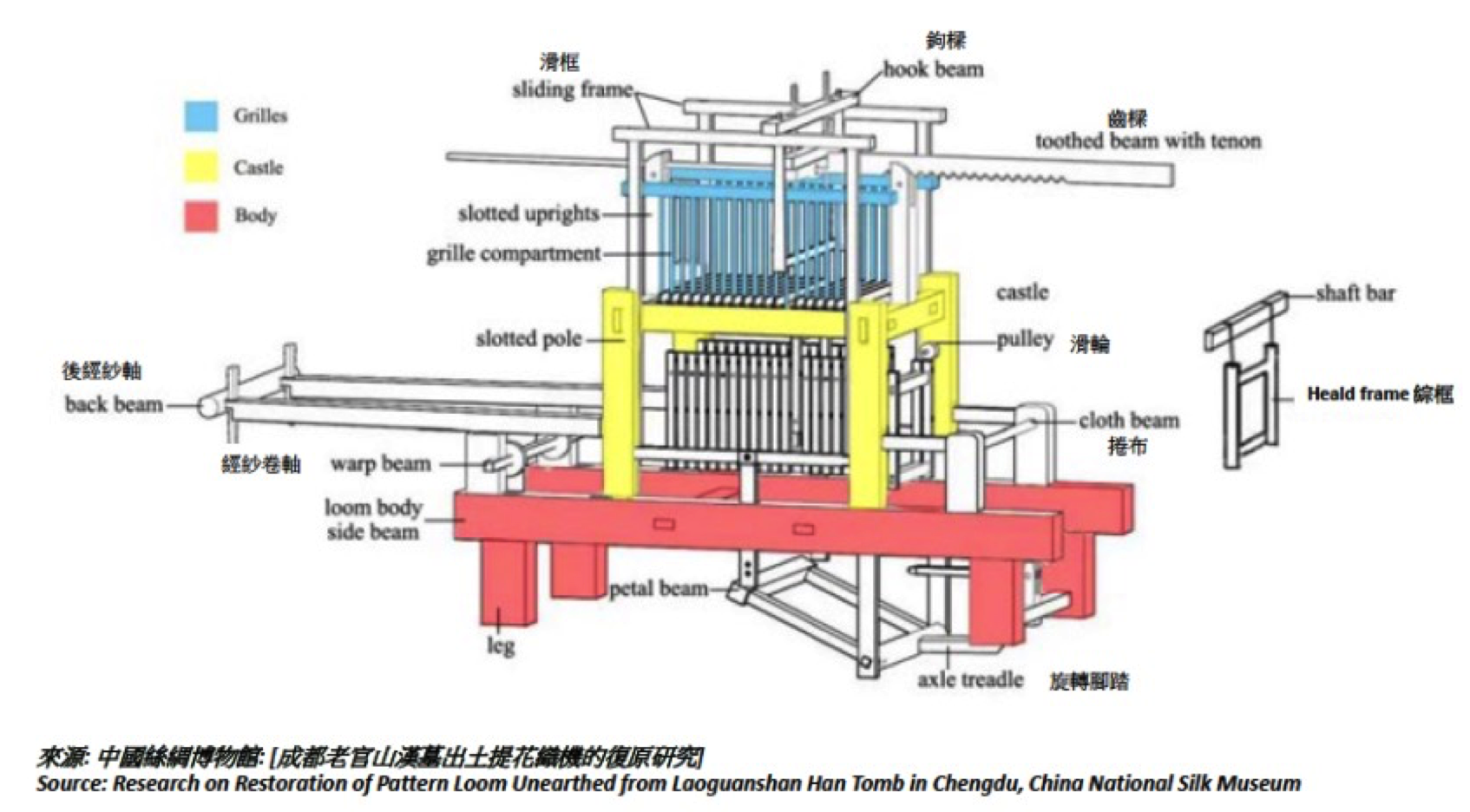

The sliding and lifting mechanism mainly includes the components of tooth beam, hook beam and double hooks, lifting poles, sliding frames, grille compartments, double talons, heald frames, pulleys, etc. The toothed beam with tennon traverse in the system to select the required frame. There is a momentum to jack up the heald frame when the operator steps down the axle treadle. The double hooks continue to catch the lifting heddle, this completes a shedding, and the shuttle passes through it. This is obviously a vertical lifting movement of the components. The axle treadle transmits the power to control the movement of the sliding frame, while the foundation treadle transmits the power to control the movement of the front harness frames.

According to the Western Zhou Dynasty, the warp yarn feeding and the fabric rolling seemed appeared, and it improved a lot in the Han Dynasty. Wang Yi “Weaving Women's Poems stated: " Axis is rotating again" showed that the weaving warps rotated. At that time, Egypt, Greece, Rome still used vertical looms, which the warp size was fixed, as there was no feeding device, so the finished fabric was limited by the length of the loom.

The book "Explanation of Names"[釋名]: "The shuttle is threaded through the middle of the loom, one is merged, and the other is tighten up" It turns out that the tools for weaving wefts in the Han Dynasty were not only shuttles, but also beating device, the "reed “for weft density. It is to tighten the weft thread left in the shed in order to prepare for the next shed. The introduction of shuttles and reeds meant that the weft-feeding technology was separated from the weft-beating process, which reflected the improvement in production efficiency and of the quality. It enabled a certain degree of mass production of brocade.

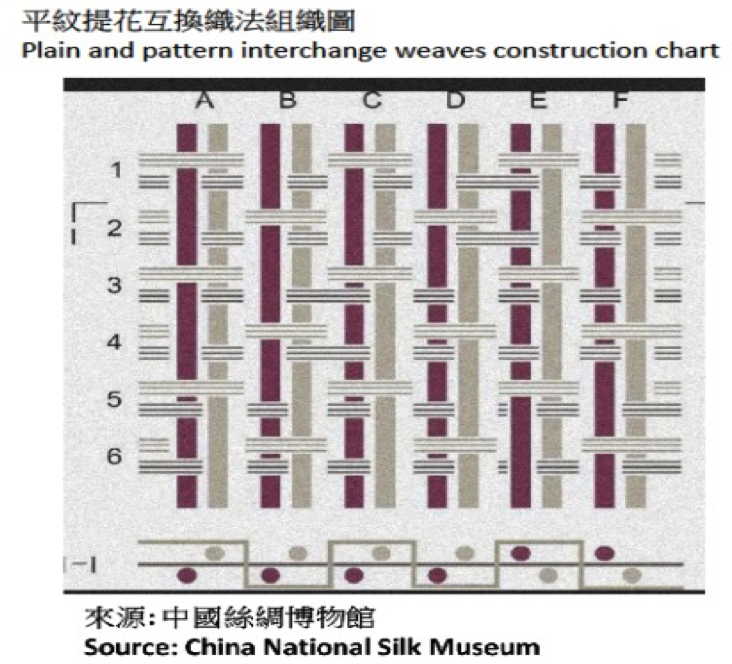

This loom is equipped with two sets of different treadle systems, which can weave both plain and pattern sheds alternatively. As a result, the finished fabric will be more consolidated and not easily deformed, which can maintain the three dimensional stability of the fabric. Thus, the shape for complicated designs and artwork are easier to show. If there is no plain weave, the finished product will be looser in construction, especially for the complex designs, as there is insufficient support for forming high three-dimensional stability. The shape and hand feeling of the brocade will be affected. In order to maintain a certain degree of it, adding plain weave alternatively is a necessity. Therefore, it is believed that the thinner weft yarn will be used for plain-weavings.

The width of a finished brocade is about 48cm, with 10,470 warps, or 219 warps per centimeter. These warps must be arranged to pass through the 84-heald frames according to the designated heddle procedure. There are also two-harness frames (also called foundation healds), one for odd-numbered warps and the other for even-numbered warps to heddle through. In order to complete the designs by fulfilling the rules of heald-heddlings, it will be a very precise, sophisticated, and lengthy work.

Moreover, you can imagine that just arranging 84 layers of pattern healds already requires a certain length for the loom. That is to say, in order to lift the height of the farthest heddle, so that the shuttle has enough room to pass through during the shedding, it requires much more height to be lifted up than the first frame. This puts a certain demand on the elasticity of the silk itself. The higher the yarn is lifted, the greater tension will be. Thus, the yarn becomes more fragile. The selection of the appropriate yarn size is very significant. Moreover, it is necessary to have someone cooperating in the activity from the "Loom Tower" or nearby. In the Han Dynasty sliding typed pattern loom, a moving hooks system on the "Loom Tower" is attaching to the necessary heald. By shedding and shuffling, the pattern is slowly woven according to the original design, repeating in cycles until a beautiful Han brocade is completed. It reflected this loom was the ingenuity one regarding to the equipment built-in and its detailed procedures during production.

Legacy of Han's Pattern Looms

Weaving a national treasured brocade is not just repeating the four steps more than 200 times mentioned above. In fact, there is a lot of preparation work behind it. Han pattern loom is a highly smart one, with many intelligent elements stored in its heald system. It can weave brocades according to precise procedures. This program can improve production efficiency and simplify weaver's work load. This kind of equipment is in line with the high-efficiency production methods advocated during the Western Industrial Revolution, but as early as the Han Dynasty in China, the mechanized textile workshops had already appeared.

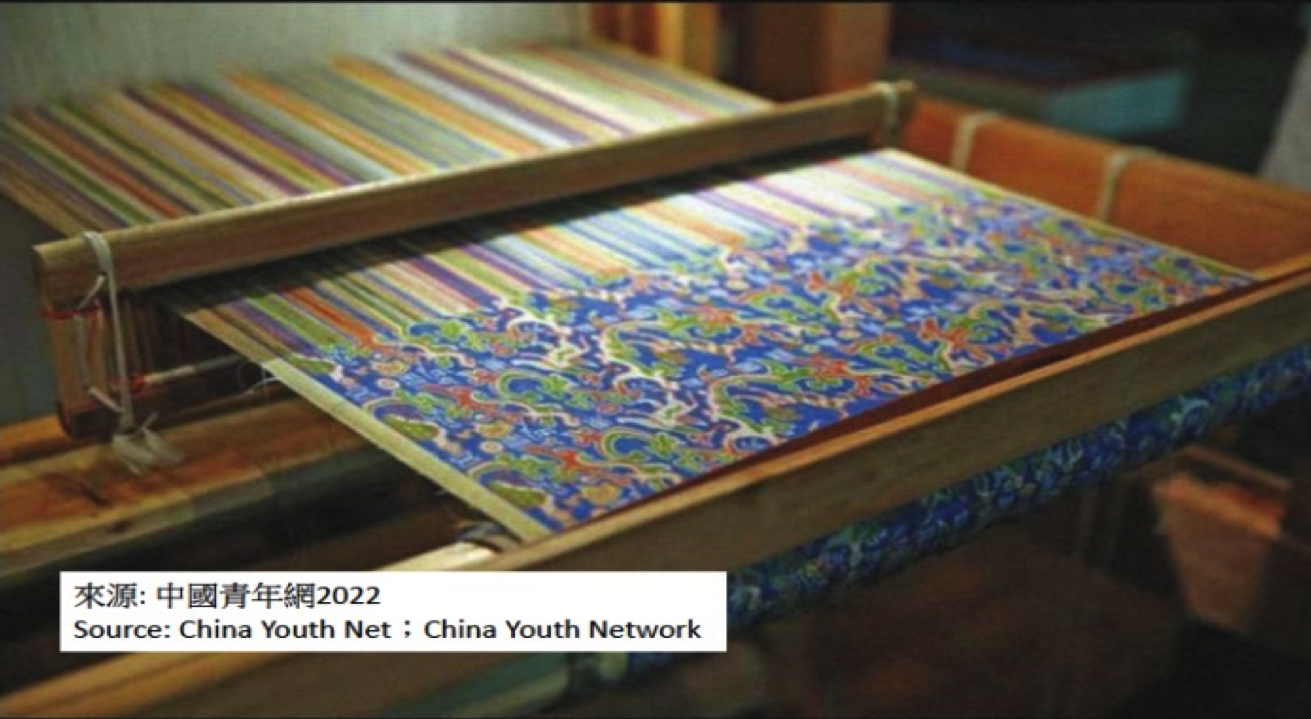

The pattern-heald drafting of the Han Dynasty used a binary encoding method similar to the modern computer programming. Making a brocade like "Five Stars Rise in the East Benefit China”, it reflected the profound foundation of ancient Chinese mathematics and culture, and showed the Eastern wisdom and compositional artistic achievements of the textile industry. This loom is like an ancient computer, and the "program" stored in embodies the wisdom of ancient humans. Han brocade has successfully inherited the glory of ancient Chinese culture with its beautiful and unique images and historical background. The weaving technology of the Han Dynasty pattern looms continued to improve and became a convenient tool to use in production, promoting the progress of the world's textile industry. The pattern loom played an important role in inheriting the past and looking to the future.

The plain-pattern weave by dual treadle system enriched textile construction and stimulated mentality in the later generations. There is no reason why the Double Weaves appeared after that. Moreover, the uses of warp feeding and fabric rolling, pulley, toothed beam and sliding frames enlightened the pattern looms in Tang and Song Dynasties.

The invention of the alternative treadled heald loom for shedding had a great impact on the history of textiles. It frees the hands of the weavers so that they can concentrate on welting and beating tasks, which greatly improves the production efficiency. At the same time, this pattern loom filled the gaps in the history of science and technology and textiles in China and the world. Han brocade weaving technology also spread out via silk trade, which is of great significance to the spread of Chinese culture, too. Moreover, it also proves that Chengdu is the southern starting point of the Silk Road.

This Han textile machine refers not only to the loom, but also to the scientific and artistic process by which human beings create material culture with its help. In fact, it includes the wit and wisdom of Chinese in the entire creation process.

Major References

1、Feng Zhao, Yi Wang, Qun Luo, Bo Long, Baichun Zhang, Yingchong Xia, Tao Xie, Shunqing Wu & Lin Xiao(2017), The earliest evidence of pattern looms: Han Dynasty tomb models from Chengdu, China, Published online by Cambridge University Press.

2、黃能馥,陳娟娟:《中國絲綢科技藝術七千年-歷代織綉珍品研究》,北京:中國紡織出版社。

3、趙豐總主編,王樂編著:《中國古代絲綢設計素材圖系-漢唐卷》,杭州:浙江大學出版社。

4、龍博:<成都老官山汉墓出土提花织机的复原研究>,中國絲綢博物館,國絲課堂2020年第16期。

5、龍博:<“五星出東方利中國”漢锦的複製>,中國絲綢博物館,國絲課堂2021年第21期。

6、趙豐、周暘、劉劍 等著:《中國紡織考古與科學研究》 ,上海:上海科學技術出版社。

7、韋黎明、李小瓊編著:《中國的絲綢》,香港:和平圖書有限公司。

8、趙豐、徐錚:《錦綉華服:古代絲網染織術》 ,北京:文物出版社。

9、趙翰生:《中國古代紡織與印染》,北京:中國國際廣播出版社。

All articles/videos are prohibited from reproducing without the permission of the copyright holder.

Welcome to leave a message:

Please Sign In/Sign Up as a member and leave a message